Understanding HSG282 And Its Importance In Holiday Lets

Holiday lets with Hot Tubs present a unique set of challenges for owners. One such challenge is ensuring that their Hot Tubs comply with the Health and Safety Executive’s guideline HSG282.

Worrying there is a lot of miss-information and unsubstantiated claims relating to HSG 282, often from unscrupulous Hot Tub businesses trying to pass off Hot Tubs as HSG 282 compliant that clearly aren’t. Don’t worry though, we aren’t going to just make claims, we’re going to quote directly from HSG 282 so you can be assured that you’re getting the right information.

This article delves into what HSG 282 is, why it’s essential for Holiday Lets, and how owners can ensure themselves and their Hot Tubs meet the requirements.

What is HSG282?

HSG282 titled “The control of legionella and other infectious agents in spa-pool systems” is a set of guidelines issued by the UK’s Health and Safety Executive (HSE) for commercial spa-pool systems such as Hot Tubs. Introduced in 2017, these guidelines are designed to manage and control risks associated with infectious agents like legionella bacteria, which can cause potentially fatal diseases like legionnaires’ disease.

It’s important to note that HSG282 is not a legal requirement, however, it’s considered ‘best practice’ and provides an essential benchmark for health and safety. In the event of a legal dispute, HSG282 may be used to assess whether a holiday let owner has fulfilled their responsibilities under the Health & Safety at Work Act 1974.

14 Although only a court can give an authoritative interpretation of the law when considering the application of health and safety legislation, HSE and local authority (LA) inspectors expect employers to follow the guidance in the ACOP (Approved Code of Practice) or be able to demonstrate compliance with the law in some other way. This document gives specific guidance, in the context of spa-pool systems, to help dutyholders comply with the health and safety legislation set out in the ACOP.

For the health and safety of your guests, and to keep on the right side of the law, you need to follow the guidance or be at risk of possible serious legal consequences.

Part 1 – What does HSG282 actually say is needed to be compliant?

We’ve read through the guidance and pulled out the parts most relevant to you, As mentioned earlier, we’re going to quote directly from the HSG282 guidance to be crystal clear what it required to be compliant.

Identifying and assessing the risk

34 Before any formal health and safety management system is implemented, the dutyholder is responsible for ensuring a risk assessment is carried out to identify the possible risks. The purpose of the assessment is to enable a decision on:

- the risk to health, ie whether the potential for harm to health from exposure is reasonably foreseeable, unless adequate precautionary measures are taken;

- the necessary measures to prevent, or adequately control, the risk from exposure to legionella and other infectious agents.

You need to do a risk assessment. If your reading this your probably already familiar with them.

37 The risk assessment enables the dutyholder to show that they have considered all the relevant factors, and the steps needed to prevent or control the risk. The Appendix provides information on the key requirements when assessing the risks associated with spa-pool systems and further information is also available in BS 8580 Water quality. Risk assessments for Legionella control.8 The assessment should consider:

- the source and quality of the supply water, eg from the mains supply or an alternative;

While it may be obvious, it’s important to consider the water source you’re going to use to fill the Hot Tub. The best source is from the mains as it’s been treated and is safe for human consumption.

1 Stop Spas Tip – If you’re using a hosepipe, let it run for a short while before filling the Hot Tub so only fresh water is used. If there is any water already in the hosepipe it may contain bacteria, especially in the summer where it can get very warm.

Competence

41 Inadequate management, lack of training and poor communication can be contributory factors in outbreaks of diseases, including legionnaires’ disease. It is important that everyone involved in the risk assessment and operation of the spa pool must be competent, trained and aware of their responsibilities. The dutyholder must ensure that suitable and sufficient information, instruction and training are provided. Competence will be a product of sufficient training, experience, knowledge and other personal qualities. Training, including refresher training, is an essential element of an employee’s capability to carry out work safely.

It’s extremely important that all staff members involved with the Hot Tub are trained and qualified. At first glance it may seem very simple, but there is a lot of important things to learn that can’t be self-taught. Certified courses such as BISHTA Water Hygiene Management from SpaTech training will give you everything you need.

Section 2: Types and settings

68 Where domestic-type spa pools are used as a business activity, the bather load is restricted to a discrete group of users.

Domestic-type spa pools – used as a business activity

76 Domestic-type spa pools or hot tubs used as part of a business activity (eg in a holiday park rental unit or hotel bedroom(s) with their own dedicated spa, or as part of a rental agreement for a single family or group use) are subject to the general duties under the HSW Act. There is a legal requirement for these systems to be managed and controlled in proportion to the risk and the risk assessment should consider the type of pool and its use. Domestic-type spa pools are for use by a small, discrete group of people at any one time and are typically:

- of either a rigid or inflatable/foam-filled structure with freeboard and skimmer;

- systems where the water should be changed after each rental/week, whichever is the shorter;

- disinfected using bromine or chlorine through the use of an inline disinfectant feeder.

A full water change needs to happen between guests or at least once a week.

Chlorine or Bromine must be used as a sanitiser and through an inline feeder.

Important take away – ANY Hot Tub that doesn’t use either Chlorine or Bromine as a sanitiser isn’t HSG282 compliant. This includes most wood fired Hot Tubs.

Section 3: Design and commissioning

84 This section gives a description of the characteristics, design, construction and commissioning of spa pools. They are designed in different shapes, sizes and with different configurations of plant and equipment, and the setting in which they are intended to be used should be taken into account in the risk assessment. Spa pools, and any modifications made to them, should be designed with safe operation and maintenance in mind. In particular, all parts should be easily and safely accessible for all essential maintenance tasks and in a way that readily allows for cleaning and disinfection of all wet surfaces. Where spa pools with a higher bather load are sited indoors, consider the dehumidification/ventilation of the area around the spa pool.

Insulation in a Hot Tub must be removable to be HSG282 compliant. A Spa that was full foam insulation doesn’t allow access to all parts and isn’t HSG282 compliant.

Circulation

89 Spa pools and plant should be designed to achieve circulation and mixing of all the treated pool water with no stagnant areas and effective removal of water from the surface (where the bulk of the pollutants are). Spa pools should be designed with a surface draw-off of approximately 80% of the circulation volume. To maintain microbiological quality of the spa-pool water, the filter and pumps should be sized to provide a turnover of pool waterthat is suitable for the pool layout and operation at the limit of the anticipated bather load, which will typically be 6 minutes for commercial-type spa pools where bather load is high and 15 minutes for lower bather loads.

No Deadlegs – Features such as waterfalls that can be turned off aren’t HSG282 compliant. If any spa water can stay still, it can breed bacteria.

The Hot Tub should have at least one pump and filter. Any Hot Tub that doesn’t have these isn’t HSG282 compliant.

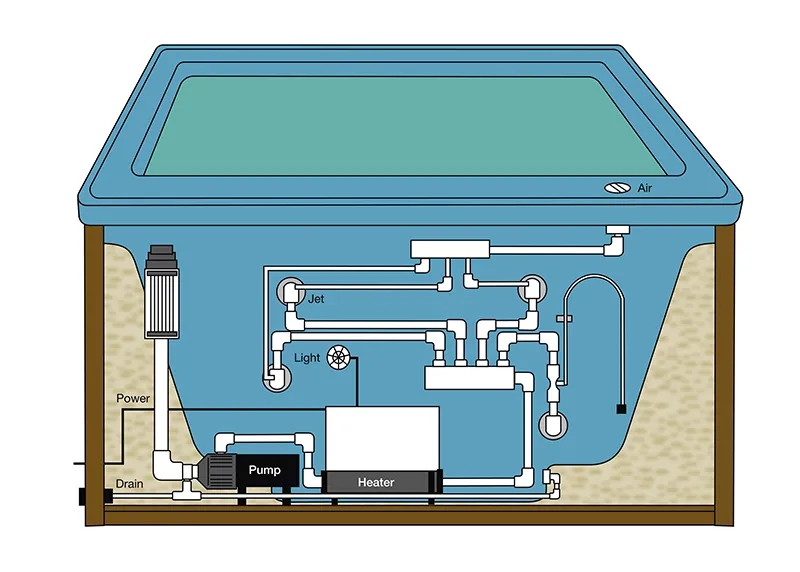

92 Figure 2 illustrates a typical freeboard and skimmer system – it shows how the water is drawn directly from the spa pool via the surface level skimmer to the filter. Water within the spa pool should be continually pumped through the filter and returned to the pool tank. There may also be a secondary circuit that draws water from the spa- pool footwell and pumps it back into the spa pool.

The Hot Tub should have at least one pump and filter. Any Hot Tub that doesn’t have these isn’t HSG282 compliant.

Pipework

93 Pipework should be designed to be readily accessible and removable for inspection and cleaning, with minimum length of pipe runs to avoid deadlegs and reduce the surface area for microbial biofilm growth. As plastic pipework may readily support microbial growth, the materials chosen should minimise the risk. Flexible, internally-corrugated piping should not be used as it increases the surface area for growth and can create areas that are difficult to clean.

Reiterating that insulation must be removable. Pipework must be smooth inside rather than corrugated.

If the pipework isn’t see through, it isn’t accessible for inspection.

Filtration

95 Filtration is necessary to ensure adequate water clarity can be maintained through the removal of suspended particulate matter/debris in the water. Filtration is a means of entrapping particles mechanically and/or through absorption onto a filter medium. There are several types of system in common use and the choice of system type and size should reflect the anticipated type of use, circulation rate and bather load. Spa pools will typically only require one filtration system but multiple units and types in sequence may be appropriate, depending upon the local circumstances.

To Be HSG282 compliant the Hot Tub must have a filtration system.

Commissioning

108 Commissioning is an essential step in ensuring that spa-pool systems operate safely from the outset. They should be commissioned to ensure they operate correctly and safely in accordance with the design parameters. It is essential that the commissioning process is carried out by competent people in a logical and defined manner and in full compliance with the supplier’s or installer’s instructions. It should include both the spa pool and any associated pipework and water treatment plant, where relevant.

109 The responsibilities of the staff carrying out the commissioning process should be clearly defined, with adequate time and resources allocated to allow the integrated parts of the installation to be commissioned correctly. The precautions taken to prevent or control the risk of exposure to legionella and other infectious agents during normal operation also apply to the commissioning process. It is important to note that a spa-pool system may harbour residual water and microbial contamination from pressure testing before leaving the manufacturer or supplier; this risk must be assessed and all components cleaned and disinfected as part of the commissioning process.

It’s extremely important that the Hot Tub is commissioned by a competent qualified professional.

Section 4: Operation and maintenance

Bather load

115 Each type of spa pool is designed to contain a maximum number of bathers at any one time and this is an important determinant of satisfactory water quality during typical use of the spa pool. The risk assessment should consider the bather load to ensure satisfactory water quality and determine the operational actions. The number of bathers in the spa pool at any time should never exceed the number of seats or loungers provided in it.

116 The design bather load is the maximum number of bathers using the spa per hour (ie each hour is three periods of 15-minute bathing followed by a 5-minute rest period) and this should be stated and not exceeded. The design bather load should be approximately 10 times the capacity of water in the spa-pool system when measured in cubic metres, with a minimum of 250 litres per bather (for example a 5 m3 pool would have a design bather load of 50 bathers per hour).

There should be a minimum of 250 litres of water per bather.

Water replacement

118 Where a hot tub or spa pool is used as a business activity, the total water volume should be replaced each week, or after each group of users, if earlier.

To remain HSG282 compliant, the Spas water must be changed after every group of users or weekly if sooner.

Water quality

120 Effective water treatment relies on filtration working in conjunction with chemical disinfection. Filtration that is working effectively and efficiently contributes to maintaining the cleanliness, clarity and safety of the water. Chemical disinfection is required to prevent microbial growth and reduce the risk of infection.

Reiterating again that the Hot Tub must have filtration and chemical disinfection.

122 The turnover time is the time taken for the entire spa-pool water volume to pass through the filters and treatment plant and back to the spa pool. The maximum design water turnover time for lower bather loads is 15 minutes, and 6 minutes for commercial-type spa pools (where there are higher bather loads).

The filtration system of a HSG282 compliment Hot Tub must turn over the entire body of water in 15 minutes or less.

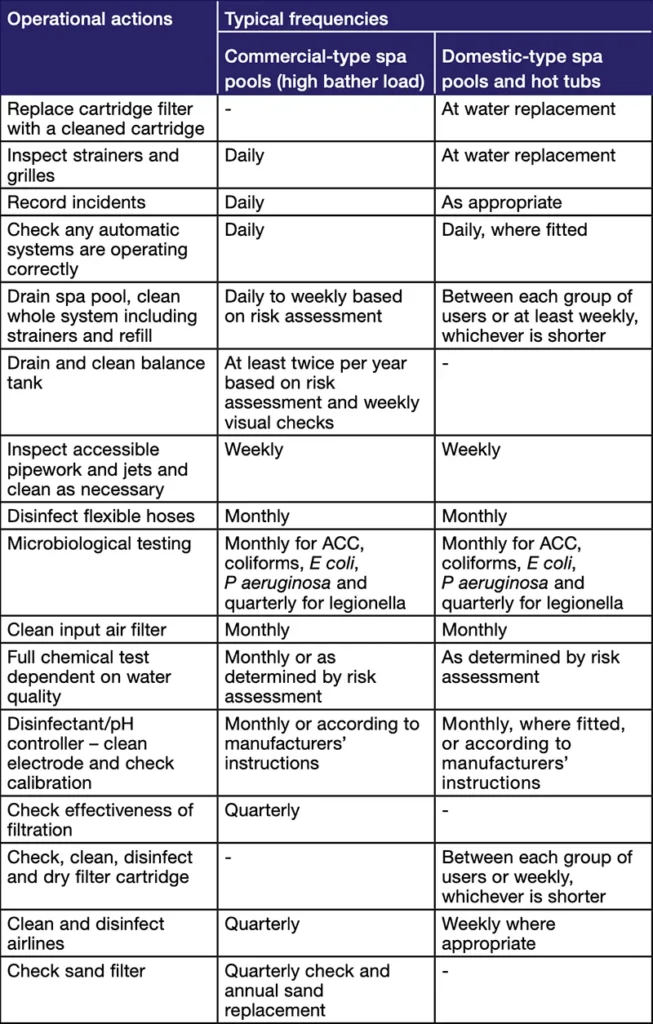

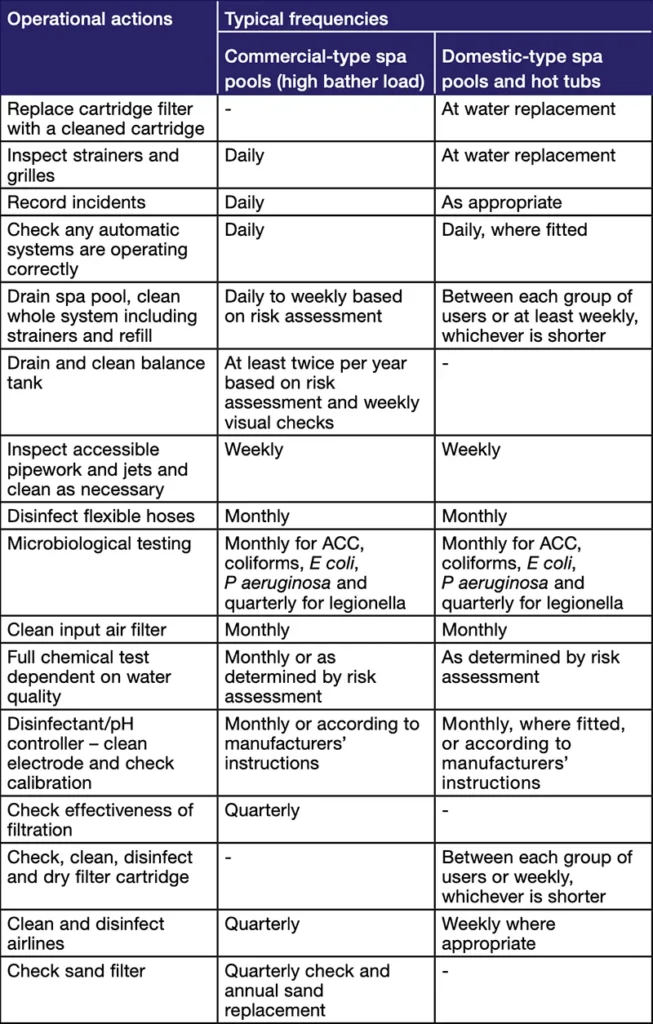

125 The frequency of inspection and monitoring of the spa-pool system will depend on the operating characteristics of the pool, its complexity, design bather load and setting, eg healthcare. The risk assessment should define the frequency of inspection and monitoring, depending on the type of use and user (particularly where there are adjustments made by the assessor to take account of local needs). Table 1 provides a checklist of operational actions and the typical recommended frequencies. Table 2 (page 38) provides guidance on the spa-pool inspection and recommended actions.

The filtration system of a HSG282 compliment Hot Tub must turn over the entire body of water in 15 minutes or less.

Table 1 Operational actions and typical frequencies – 1

Table 1 Operational actions and typical frequencies – 2

Table 2 Guidance on inspection and recommended actions

129 The pH, total alkalinity, total dissolved solids (TDS), temperature and calcium hardness of water are the main factors in determining the balance of the water. Balanced water is neither scale forming nor corrosive and may be measured using a number of indices (such as the Langelier Saturation Index or Ryznar Stability Index). Water balancing may not be required in spa pools with a higher bather load due to the frequency of water replacement and draining of the spa pool.

The water in the hot tub must be correctly balanced.

130 The most important factor in water balance is pH which should be maintained between pH 7.0–7.6. Depending on the nature of incoming mains water and the disinfectant used, the pH of the water may need to be adjusted by the use of chemical treatment to ensure the disinfectant remains effective (see Information box 4 Adjusting the pH).

The pH of the water must be between 7.0 & 7.6. Chemical treatments can be used to achieve this.

Information box 4 Adjusting the pH

The nature of the incoming mains water supply tends to determine the pH adjustment required. Bromine products (eg 1-bromo-3-chloro-5,5- dimethylhydantoin) as well as some chlorine products (eg sodium dichloroisocyanurate dihydrate) tend to be relatively neutral when dissolved in spa-pool water and have little effect on the pH. Heating water drives off acidic carbon dioxide so the natural tendency is for the pH to rise in spa pools.

Products such as trichloroisocyanuric acid form an acidic solution (pH 3) in some but not all water supplies and an alkaline pH adjuster will be required to increase the pH to within the maximum range (pH 7.0–7.6), eg soda ash (sodium carbonate).

Sodium and calcium hypochlorite will result in an alkaline pH so an acid pH adjuster will be required. Acidic pH adjusters include sodium hydrogen sulphate (sodium bisulphate) and for commercial spas, hydrochloric acid.

131 The TDS are the measure of the concentration of dissolved materials present in the water from the water treatment chemicals and bathers. The TDS of the spa-pool water should be no more than 1000 mg/l higher than the incoming fill water, above which corrosion of the water distribution system may become more apparent. Planned regular water replacement will normally prevent such occurrences.

Water changes should be done regularly enough to prevent TDS of the water exceeding 1000 mg/l higher than the incoming fill water.

Section 5: Testing and monitoring water quality

143 The risk from exposure to legionella and other infectious agents should be prevented or controlled and the precautions taken monitored to ensure they remain effective. This section gives guidance on monitoring the water quality in spa-pool systems, routine sampling and testing for the presence of bacteria. These combined factors will help to give an indication of whether control is being achieved.

The guidance given to monitor and control the water quality must be followed.

144 Spa-pool water should be routinely analysed to ensure the continued effectiveness and suitability of the treatment programme. The frequency and extent of any analysis will depend on the operating characteristics of the system and will typically include daily, monthly and/or quarterly actions to ensure that chemical dosage and system water quality are appropriate – see Table 1 Operational actions and typical frequencies (page 34).

Typical frequencies of water maintenance outlined in tables below.

Table 1 Operational actions and typical frequencies – 1

Table 1 Operational actions and typical frequencies – 2

147 Testing of water quality, using chemical and microbiological monitoring, is an essential part of the spa-pool treatment regime and may be carried out by the operator where they are suitably trained to do so, or by an external service provider.

Water monitoring and treatment should be carried out by a trained operator or by an external service provider.

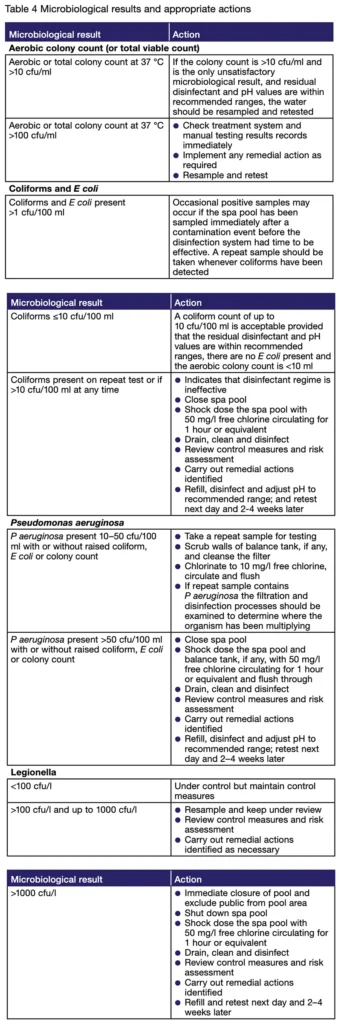

148 Testing and recording of the chemical and microbiological parameters associated with the spa pool should be carried out and appropriate actions taken according to the results (see Tables 3 and 4). The test results should be provided in the form of a report which will form part of the record-keeping requirements.

Water testing parameters and actions detailed in the below tables. The results should be recorded for record keeping.

Chemical

149 The frequency and extent of the chemical testing should be determined by the risk assessment. Most testing can be done at poolside but some specialist tests will require laboratory analysis.

A risk assessment should be conducted to determine the testing frequency. For example, the recommended frequency may need to be modified if there is particularly excessive use.

150 Testing of spa-pool water should capture normal variation of operating conditions, for example it should be carried out when the features are not operating as spa-pool water chemistry alters during activation of the booster jets, and ideally should also be carried out just after maximum use to ensure the treatment regime is working appropriately.

Testing shouldn’t be done when the Hot Tub is in use. It should be done just after maximum use.

For Hot Tubs in Holiday Lets these are the key parts and what often catch people out, however, we always recommend that you read the HSG 282 guidance in full.

Part 2 – Myths of HSG 282

Myth 1 – No Headrests

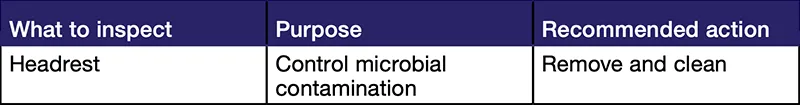

We hear this one a lot and it’s a head scratcher. Nowhere in HSG 282 does it mention or even give the slightest suggestion that you can’t have headrests to be compliant, the opposite in fact.

The truth – You can have Headrests and be HSG282 compliant.

Its clearly stated and even gives the word Headrests in table 2 under part 133 of the Cleaning and disinfection section. As part of your cleaning routine they just need to be removed and cleaned. This links with what is mentioned earlier in part 84, that all parts should be accessible for maintenance and cleaning.

84 This section gives a description of the characteristics, design, construction and commissioning of spa pools. They are designed in different shapes, sizes and with different configurations of plant and equipment, and the setting in which they are intended to be used should be taken into account in the risk assessment. Spa pools, and any modifications made to them, should be designed with safe operation and maintenance in mind. In particular, all parts should be easily and safely accessible for all essential maintenance tasks and in a way that readily allows for cleaning and disinfection of all wet surfaces. Where spa pools with a higher bather load are sited indoors, consider the dehumidification/ventilation of the area around the spa pool.

Table 2 Guidance on inspection and recommended actions

Myth 2 – Wood fired Hot Tubs

With a rustic appearance, woodfired Hot Tubs are sometimes seen on Glamping sites. If you’ve read this far you will have learned about several parts of HSG 282 that most Wood fired Hot Tubs don’t come close to meeting. These include:

95 Filtration is necessary to ensure adequate water clarity can be maintained through the removal of suspended particulate matter/debris in the water. Filtration is a means of entrapping particles mechanically and/or through absorption onto a filter medium. There are several types of system in common use and the choice of system type and size should reflect the anticipated type of use, circulation rate and bather load. Spa pools will typically only require one filtration system but multiple units and types in sequence may be appropriate, depending upon the local circumstances.

120 Effective water treatment relies on filtration working in conjunction with chemical disinfection. Filtration that is working effectively and efficiently contributes to maintaining the cleanliness, clarity and safety of the water. Chemical disinfection is required to prevent microbial growth and reduce the risk of infection.

122 The turnover time is the time taken for the entire spa-pool water volume to pass through the filters and treatment plant and back to the spa pool. The maximum design water turnover time for lower bather loads is 15 minutes, and 6 minutes for commercial-type spa pools (where there are higher bather loads).

The Truth – Very few Wood fired Hot Tubs without major modification are HSG 282 compliant.

Part 3 – What Do you Need To Do To Be HSG 282 Compliant

1 – Do a Risk Assessment.

2 – Choose the right Hot Tub (HSG 282 compliant)

3 – Monitor and control water Quality.

4 – Keep Records

Conclusion

Compliance with HSG 282 is an essential aspect of managing a Holiday Let with a Hot Tub. While ensuring compliance might require some investment of time and resources, it is undoubtedly worthwhile for the safety of guests, the legal protection of the owner, and the reputation of the business.